When exhaust exceeds this temperature, back off on the throttle.ĪNALYZE OIL AND LUBES.

Then, consult an engine shop as to the maximum exhaust temperature that is considered satisfactory. If your dash doesn’t already include an exhaust pyrometer, install one. Here are a few pointers to minimize impact of engine alterations if you decide to do so: Transmission, driveshaft and rear axle manufacturers design their products to precisely match the level of torque they are specified for. Increasing the torque sent through the drivetrain can cause serious trouble, too. It could also over-speed the turbo and cause erosion of the turbine blades on the exhaust side.

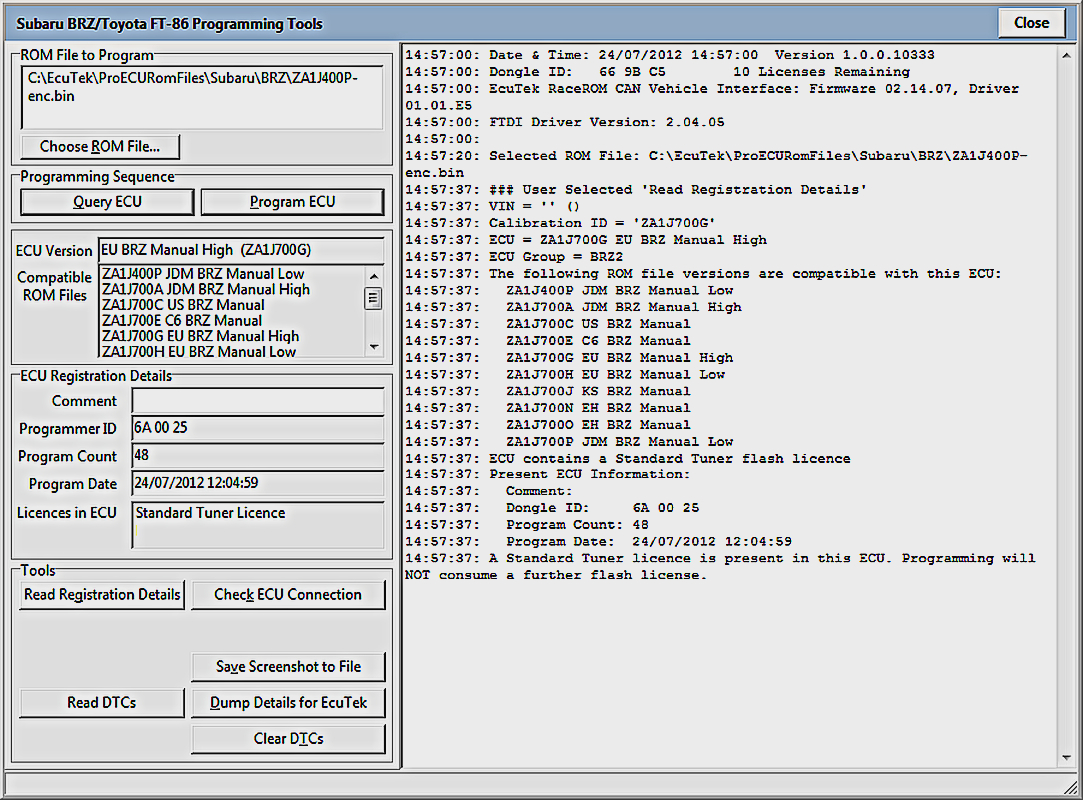

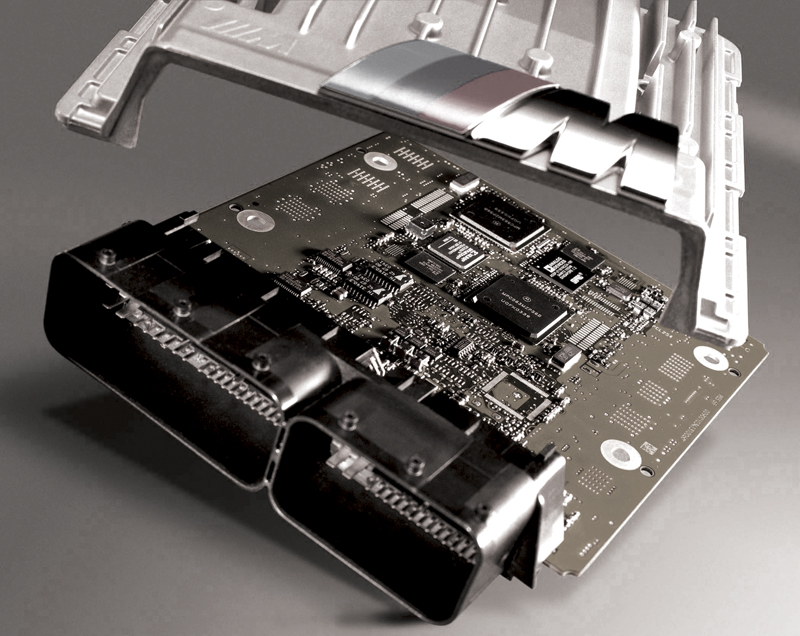

It’s also bound to send Nox emissions through the roof and, along with them, peak cylinder pressures and the amount of heat your cooling system and engine oil will have to remove from cylinder liners, pistons and other parts.Ī drastic increase in power is likely to significantly increase oil soot, caused by the greatly increased ratio of fuel and air going into the cylinders. Re-flashing your ECM or remotely advancing injection timing and the quantity of fuel that goes in for each power stroke could certainly give an underpowered, fuel-thirsty truck a boot in the rear.

Pitt Power engineers are constantly researching modern engines and ECMs to determine what can be improved, he says.

“If you can do just a mile or a mile and a half better, you’re going to put about $20,000 extra in your pocket each year,” he says. He hasn’t tracked the exact fuel mileage benefits, but says he did gain nearly 150 horsepower – currently at 580, up from the stock 435.įuel costs can be cut and power squeezed from stock ECM programming, says Pittsburgh Power owner Bruce Mallinson, whose company specializes in diesel engine performance and does the type of work Backlund had done. “It’s been a night and day difference with fuel economy and power,” Backlund says.

0 kommentar(er)

0 kommentar(er)